Find your nearest LINE-X Store.

Download this Case Study

SITUATION

A trommel screen, also known as a rotary screen, is a mechanical screening machine used to separate materials, mainly in the mineral and solid-waste processing industries. In mining, trommel screens provide a simple mechanism to classify and sort large volumes of mill product to a suitable size range to be used in the crushing stage. Trommel Screens are attached to the end of grinding mills and scrubbers to perform a variety of screening functions. The trommel surfaces, including the frames exposed to the milled product, are subject to intense abrasion and therefore corrosion if the protective coating fails.

An engineering company in the West Australian goldfields were seeking an alternative to the coating that failed to protect a mill frame and required a strong abrasive resistant coating.

SOLUTION

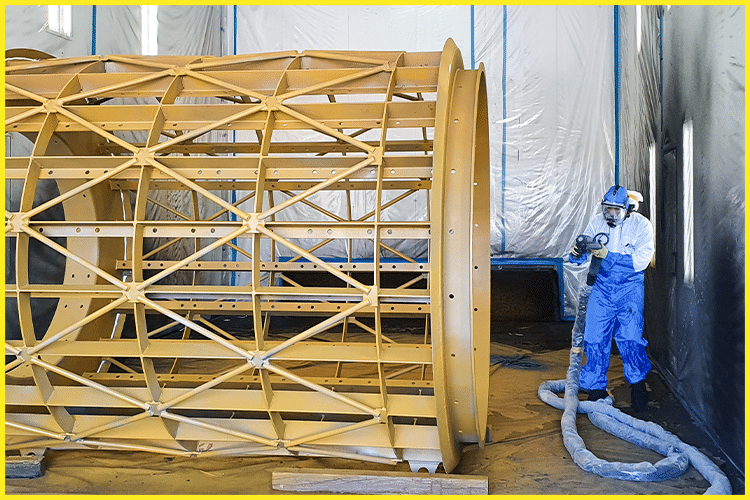

LINE-X was engaged to find a solution and XS-350 was selected for its strong long-lasting properties. The existing coating was removed, and weld repairs carried out prior to arrival. The frame size was 3.2m long with a diameter of 2.6m and weighed approximately 3 tonnes. After sandblasting and a sealant treatment to fill holes and gaps, Fast Cure Primer was applied.

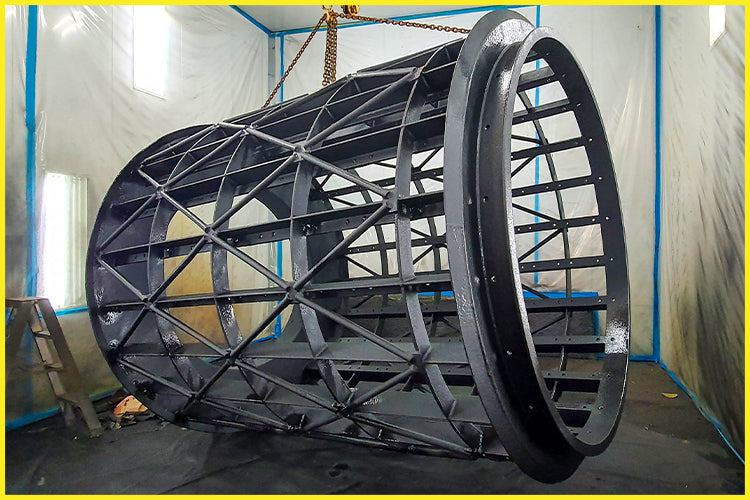

Two LINE-X applicators simultaneously sprayed the XS-350 to an average 3-4mm thickness ensuring a consistent protective coating. The whole process and application took several hours to complete and overnight to fully cure.

RESULTS

The client was extremely happy with the result and has since manufactured a new frame for a different project and insisted it be coated with LINE-X prior to delivery as a preventative maintenance tool.

All mine sites want to reduce unexpected downtime due to machine breakdown or failure, so tough and long-lasting protective coatings are essential for harsh operating conditions.