Find your nearest LINE-X Store.

Download this Case Study

SITUATION

A brewpub in Western Australia had an existing floor coating that was failing severely – posing health and safety risks to its employees and reducing productivity throughout the day. Breweries can be tough conditions for flooring systems to weather – the heat, moisture, and constant traffic can quickly cause them to break down. The company needed an extremely durable solution with a quick return to service.

SOLUTION

Many of the most heavily affected areas were around the main production footprint, where they are exposed to moisture, high temperature, and impact from equipment such as kegs. The experts at LINE-X Flooring Systems examined the site and decided on the perfect solution for the client. Our applicators are extensively trained and licensed to install a wide variety of flooring applications, meaning the client always gets the right product for the job.

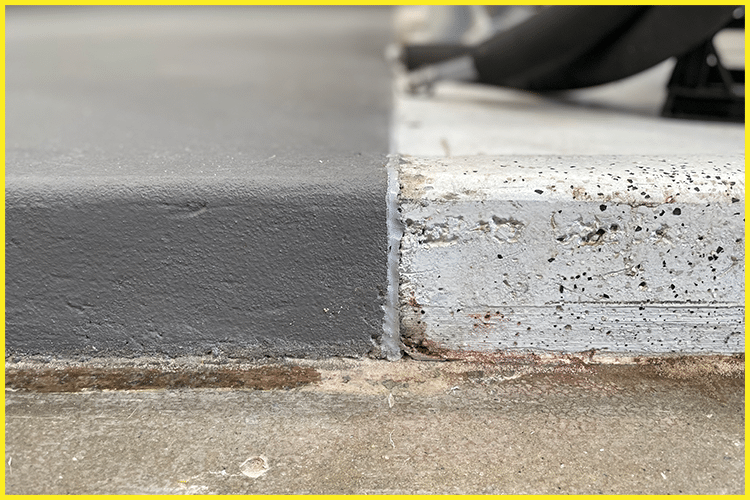

The area was first prepared by diamond grinding the concrete, installing hand-troweled epoxy coving, and chasing 4mm deep anchor points around the perimeter and floor wastes prior to pouring the Base Coat. Fine kiln-dried sand was then broadcasted into the Base Coat to achieve a P4 Non-Slip Rating. Within 4 hours, the applicators were back on the floor vacuuming the excess sand in preparation for the next step. A Top Coat is then applied to seal the application and the floor is ready to walk on after just three hours!

RESULTS

PU cement was an excellent solution for the areas exposed to chemicals, high-abrasion, and extreme temperatures – while still being able to accommodate quick turnaround times due to its’ fast-curing characteristics. The wealth of knowledge at their disposal means LINE-X Flooring Systems always chooses the right solution for the job.