Find your nearest LINE-X Store.

Download this Case Study

SITUATION

Malting is the process of converting barley or other cereal grains into malt for use in brewing, distilling, or in foods. The malting process starts with drying the grains until they reach a specific moisture content, then immersing or steeping in water in large batches for up to three days to allow the grain to absorb moisture and start to sprout. Industrial steep tanks face continuous exposure to moisture and are prone to pitting and corrosion as a result. Cargill, one of the largest purchasers and distributors of grain and other agricultural commodities, sought a new way to upgrade their malt steeping process in Australia.

To improve the cosmetics and performance of the steeping tank, Cargill needed to resurface the lining of the tank. The lining had to be watertight, withstand impact and abrasion to provide a corrosion free barrier. The team weighed the different products on the market and chose a polyurea coating from LINE-X Australia.

SOLUTION

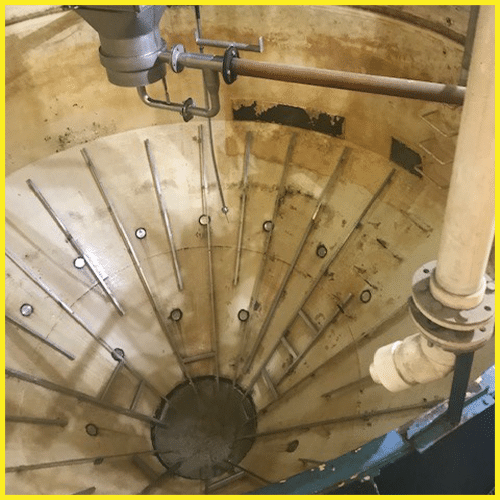

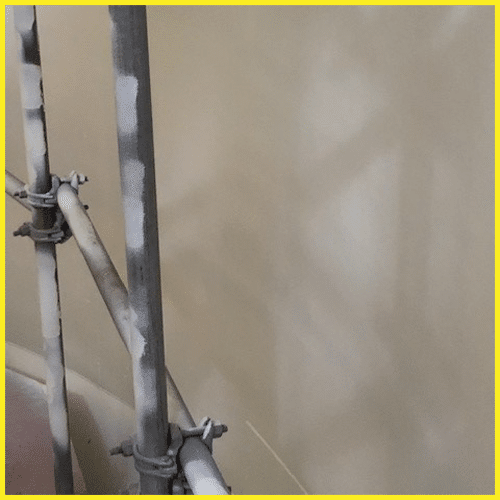

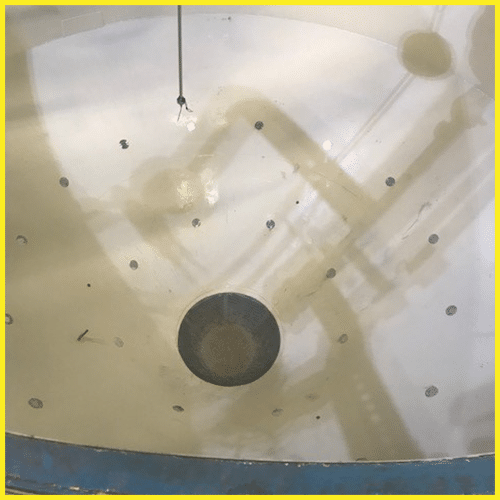

The malt steep tanks were drained and scrubbed before the 6-day LINE-X application process began. To begin, LINE-X applicators constructed scaffolding so personnel and equipment could access the interior of the tanks. Next, all 110 square meters (1184 square feet) of the tank’s interior was sandblasted to remove all corrosion and other defects. After two days of sandblasting, the surface was ready for a proprietary LINE-X primer. The primer is specially formulated to maximise adhesion between the LINE-X coating and the substrate. Once primed, LINE-X XS-350 pigmented in white was spray applied to a thickness of 3mm. LINE-X 350 is a pure polyurea coating with high-performance physical properties including moisture insensitivity and fungus resistance which is perfect for storage tank encapsulation.

RESULTS

Cargill is steadily upgrading the remaining malt steep tanks in this facility. The team at LINE-X is expected to spray two additional steeping tanks in the same manner. By trusting LINE-X, Cargill is investing in its industrial infrastructure which supports agricultural services, manufacturers, and food service companies along the worldwide supply chain.