Find your nearest LINE-X Store.

Download this Case Study

Situation

The largest producer of reclaimed glassware in the world uses a sand blaster to frost their goblets and tumblers. Due to the force of the sand blasting, the original door made of 5mm thick mild steel eroded forming a hole within approximately 12 weeks’ time costing the company replacement fees and production downtime.

The customer required a solution that would withstand powerful blasts on a continuous basis preventing downtime from its production schedule.

Procedure

A 1.5mm galvanized steel panel was used. The panel was shot blasted to increase the surface profile, primed and then sprayed 5mm thick with LINE-X® XS-100 protective coating.

Solution

LINE-X XS-100 was chosen due to its high impact absorption properties and sprayed on a 1.5mm galvanized steel panel to replace the original steel door.

Results

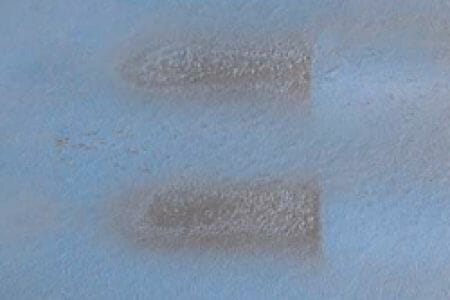

The panel was subject to high pressure sand blasting for a period of 6 months, after which it was returned to LINE-X for evaluation. The results were outstanding. In the 6 month period, only 2.5mm of the LINE-X had been worn away under the harshest conditions for industrial applications.

Compared to the steel panel, the 5mm thick LINE-X panel is expected to last 12 months. In this timeframe, previously the client would have had to replace 9 of the 5mm thick mild steel doors.

“The application of LINE-X to the sand blaster door has resulted in over 50% less downtime of the machine and considerable savings in the cost of replacement doors.”

– Managing Director Green Glass