Find your nearest LINE-X Store.

Download this Case Study

SITUATION

A transport company using a fleet of tip trucks found that the materials being hauled in the trucks caused serious damage to the truck beds. The trucks experienced issues with hang up as well as leeching hydrochloric acid. This resulted in increased maintenance cycles and upkeep costs.

The client required a product that would protect against corrosion, rust, and dents while also allowing the material being hauled to slide out when necessary.

SOLUTION

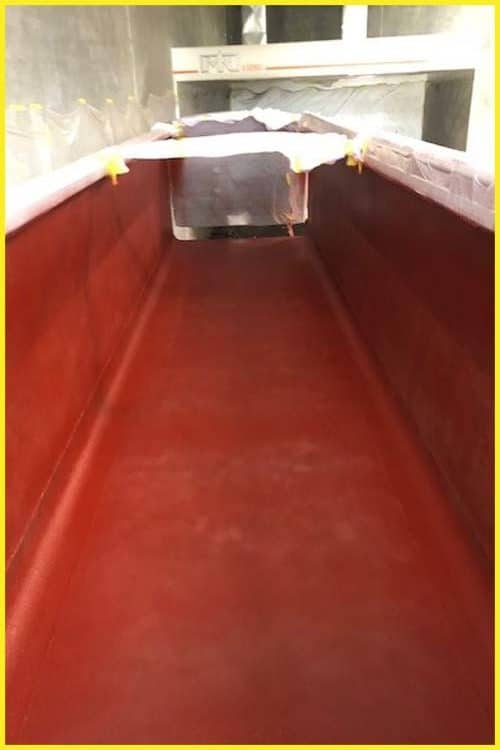

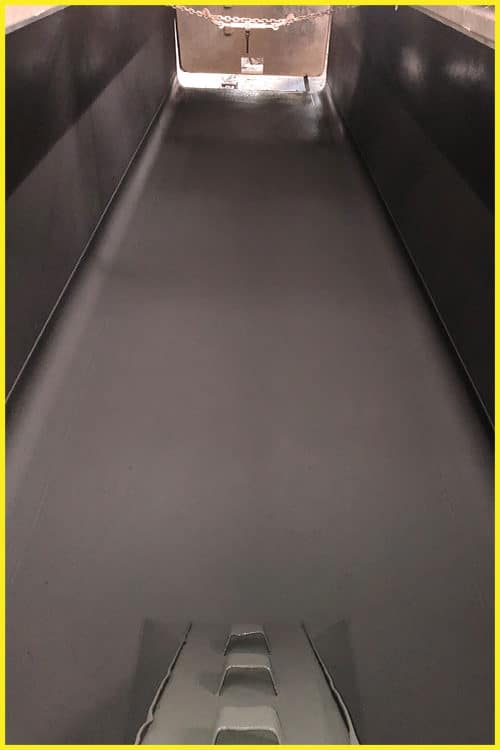

The tip truck was sandblasted at a local facility and brought to the LINE-X shop. At a minimum, dump trucks should be commercial blasted, but a white blast is the preferred method for high impact applications. The vehicle was primed using LINE-X XPM Primer before spraying LINE-X XS-350 to a 3mm nominal thickness.

XS-350 is a protective coating specially designed to resist excessive impact, abrasion, and even chemical spills. The tip truck was delivered back to the customer and ready for unrestricted use in 48 hours.

RESULTS

LINE-X XS-350 provided the protection against impact, abrasion, corrosion, and chemical spills that the client required while still allowing material to slide out of the truck when necessary. The entire job was completed in 3 days, meaning the client could get back to business without the stress of constant maintenance costs.