Find your nearest LINE-X Store.

Download this Case Study

Situation

Companies in North America have the constant challenge of keeping their equipment looking clean and new. Flat deck trailers aren’t immune to this problem. Steel decks require routine maintenance and repainting to keep on top of corrosion problems. Wood decks rot and are difficult to clean. Aluminum doesn’t suffer the same corrosion problems, but abrasion tends to cause excessive wear. Customers in the market for new trailers are demanding quality, with problem free coatings.

Procedure

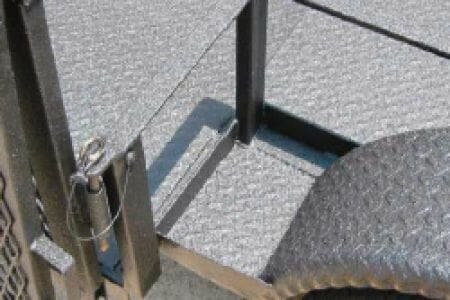

On new, structurally sound paint, area to be coated is masked, cleaned and abraded for the LINE-X protective coating. For used recreational equipment, the cleaning process includes sand blasting and removal of any pre-existing corrosion, loose paint, etc. Accessories are carefully protected and/or removed as necessary. Cleaned substrates are then primed with LINE-X primer and coated with the appropriate LINE-X coating through our heated high pressure impingement application equipment. Topcoat can be applied if requested. Following application of LINE-X, the unit is unmasked, accessories are replaced and it’s ready to go. Full cure is complete in 24 hours.

Solution

LINE-X Protective Coatings are suitable for all trailer materials. Applied over a properly prepared substrate, LINE-X will eliminate corrosion and abrasion issues, as well as provide chemical and impact resistance.

Results

A LINE-X protected deck enhances safety of the unit in terms of load slippage and also helps prevent static build-up problems. Ease of cleaning means greatly reduced maintenance requirements and ongoing good looks. Frame components are ideally coated with LINE-X Protective Coatings, as well as side walls, fenders and accessories