Find your nearest LINE-X Store.

Download this Case Study

SITUATION

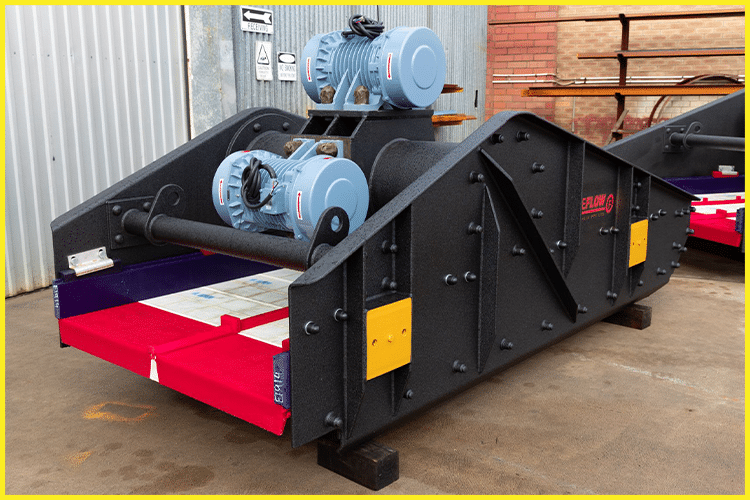

A vibrating feeder is a piece of equipment that uses vibration to feed material to a processor or machine. Vibrating feeders use both vibration and gravity to move material. Gravity is used to determine the direction, either down, or down and to a side, and then vibration is used to move the material. They are mainly used to transport many smaller objects.

In harsh environments, such as a remote mine site, feeders and screens are subject to heavy corrosion. Painted surfaces do not handle highly abrasive and acidic conditions well – so superior protective coatings like LINE-X Polyurea’s are ideal.

SOLUTION

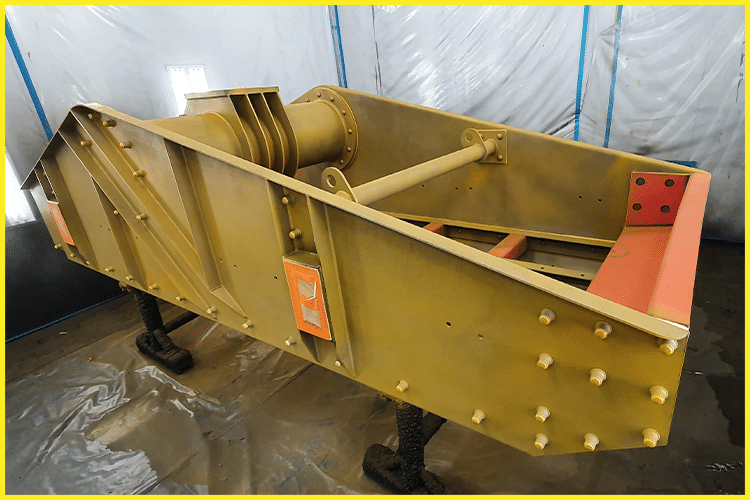

Screens are specifically designed to suit each operation and come in a wide range of sizes – from less than a meter to several meters in length and width. LINE-X XS-350 was chosen to encapsulate such screen frames whether they be used for screening, sorting, or dewatering etc.

In each case the heavy steel frames are sandblasted to create the correct profile and prior to priming with FCP all the weld joins and huck bolt ends are sika flexed to unsure a full encapsulation. The XS-350 is sprayed to an average 2mm thickness depending on application and a little heavier on the potential wear areas. Each vibrating feeder frame was blasted, primed, and coated in one day before being returned for fitting out and testing prior to delivery to site.

RESULTS

By encapsulating the frame, the LINE-X protective coating is expected to double the service time of the vibrating feeder avoiding costly maintenance. The client had a goal – reduce potential expensive maintenance down time by installing durable, dependable, easy to clean equipment, and LINE-X had the solution to make that goal a reality.